Material and tool

1. Introduce material in daily life

1.metal

Aluminum

Features:

Light: Aluminum is a lightweight metal, lighter than iron, and has good strength and corrosion resistance.

Electrical conductivity: Aluminum is a good conductor of electricity, so it is widely used in power transmission and electronic devices.

Corrosion resistance: Aluminum has good corrosion resistance and can be used for a long time in humid and corrosive environments.

Daily application:

Packaging containers: Aluminum cans and aluminum foil are common packaging containers used to carry beverages, food and cosmetics. Their lightness and corrosion resistance make them ideal packaging materials.

Kitchen utensils: aluminum POTS, pans and baking pans and other kitchen utensils have good heat conduction performance, so that food can be evenly heated, so as to maintain the taste and nutrition of food.

Building materials: Aluminum alloys are commonly used to make building components such as window frames, doors and exterior wall panels, and are favored for their light weight and corrosion resistance.

Aluminum alloy

1. Classification of aluminum alloy

A series :1000 series aluminum alloy represents 1050, 1060, 1100 series. In all series, the 1000 series belongs to a series with more aluminum content. Purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively single, the price is relatively cheap, and it is a series commonly used in conventional industry. At present, most of the 1050 and 1060 series are in circulation on the market. 1000 series aluminum plate according to the last two Arabic numerals to determine the minimum aluminum content of this series, such as 1050 series after the two Arabic number is 50, according to the international brand naming principle, the aluminum content must reach 99.5% or more for qualified products. China's aluminum alloy technical standard (gB/T3880-2006) also clearly stipulates that the aluminum content of 1050 reaches 99.5%. In the same way, the aluminum content of the 1060 series aluminum plate must reach more than 99.6%.

The second series :2000 series aluminum alloy represents 2024, 2A16 (LY16), 2A02 (LY6). The 2000 series aluminum plate is characterized by high hardness, of which the copper original content is the highest, about 3-5%. The 2000 series aluminum rod is an aviation aluminum material, which is not often used in conventional industry.

Three series :3000 series aluminum alloy represents 3003, 3A21 mainly. China's 3000 series aluminum plate production process is more excellent. 3000 series aluminum rod is made of manganese element as the main component. The content is between 1.0-1.5, which is a series with good anti-rust function.

Four series :4000 series aluminum rod represents 4A01 4000 series aluminum plate belongs to the series with higher silicon content. The silicon content is usually between 4.5-6.0%. Construction materials, mechanical parts, forging materials, welding materials; Low melting point, good corrosion resistance, product description: with heat resistance, wear resistance

Five series :5000 series aluminum alloy represents 5052, 5005, 5083, 5A05 series. 5000 series aluminum rod belongs to the more commonly used alloy aluminum plate series, the main element is magnesium, and the magnesium content is between 3-5%. Can also be called aluminum magnesium alloy. The main characteristics are low density, high tensile strength, high elongation and good fatigue strength, but it can not be strengthened by heat treatment. Under the same area, the weight of aluminum magnesium alloy is lower than that of other series. It is also widely used in conventional industry. 5000 series aluminum plate is one of the more mature aluminum plate series in China.

Six series :6000 series aluminum alloy represents 6061 mainly contains magnesium and silicon two elements, so the advantages of 4000 series and 5000 series are concentrated 6061 is a cold treatment aluminum forging products, suitable for applications with high corrosion resistance and oxidation requirements. Good usability, easy coating, good processability.

Seven series :7000 series aluminum alloy represents 7075 mainly containing zinc. Also belongs to the aviation series, is aluminum magnesium zinc copper alloy, is heat treatable alloy, belongs to super hard aluminum alloy, has good wear resistance. It also has good weldability, but poor corrosion resistance. At present, we basically rely on imports, and our production technology needs to be improved.

2.plastic

Plastic: Polyethylene (PE)

Features:

Lightweight: Polyethylene is a lightweight plastic with good strength and durability.Corrosion resistance: polyethylene has good corrosion resistance and can be used for a long time in various chemical environments.

Plasticity: Polyethylene has good plasticity and can be made into various shapes by injection molding, extrusion and blow molding.

Daily application:

Packaging materials: Plastic bags and bottles are common applications for polyethylene, which is used to package food, beverages and other goods. Their lightness and durability make them an indispensable item in everyday life.

Household items: Polyethylene is also commonly used to make a variety of household items, such as plastic chairs, toys, POTS and buckets. These products usually have good durability and cost effectiveness.

3.composite

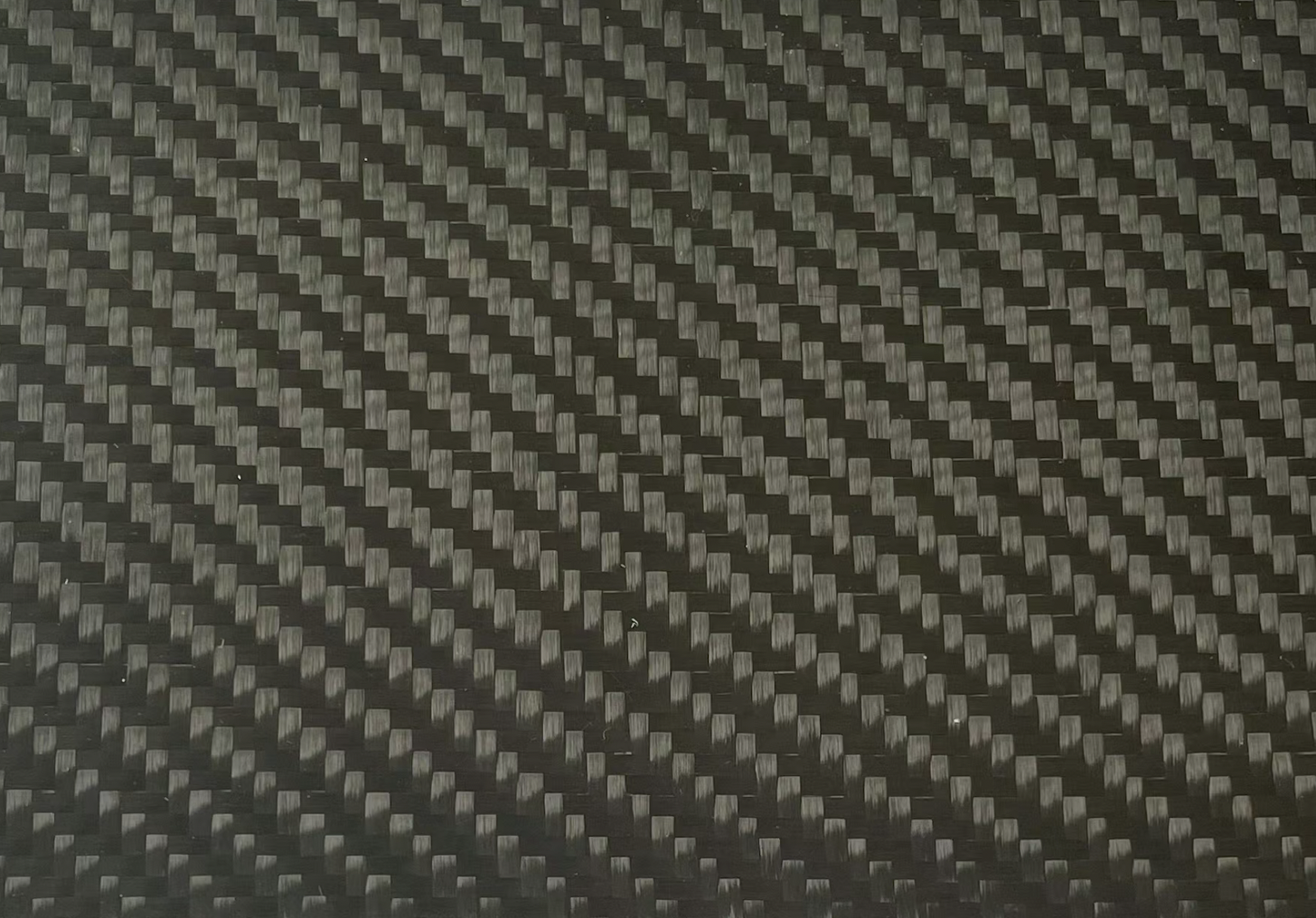

Composites: Carbon Fiber Reinforced Polymer (CFRP)

Features:

High strength: CFRP has higher strength and stiffness than steel, making it have excellent structural properties.

Lightweight: CFRP is lighter than steel, so it can reduce structural load and improve product performance.

Corrosion resistance: CFRP has good corrosion resistance and can be used for a long time in humid and corrosive environments.

Daily application:

Sports equipment: Advanced sports equipment, such as bicycles, golf clubs, tennis rackets and snowboards, are often made of CFRP. The high strength and stiffness of CFRP make these devices lighter, more durable, and have excellent performance and control.

Automotive manufacturing: CFRP is also used to manufacture automotive body parts such as roofs, doors and body frames. By using CFRP, automakers can reduce the overall weight of vehicles, improve fuel efficiency, and enhance vehicle safety and performance.

2. new materials

1. Graphene:

Structure and nature:

Graphene is a two-dimensional lattice of carbon atoms arranged in a hexagonal shape, a single-layer structure of graphite. Due to its unique structure, graphene has many extraordinary properties, including ultra-high electrical conductivity, thermal conductivity, mechanical strength, and flexibility.

Graphene's electrons move freely on a two-dimensional plane, so it is a zero-gap material with excellent electron transport properties and is considered to be one of the ideal materials for future electronic devices.

Application field:

Electronics: Graphene can be used to make high-performance transistors, field-effect transistors (FETs), and transparent conductive films for applications in electronic displays, solar cells, and sensors.

Energy storage: Graphene, with its high surface area and excellent electrochemical properties, is being studied for the preparation of high-performance lithium-ion batteries, supercapacitors and fuel cells.

Material strengthening: Graphene can be used as a strengthening agent, compounded with other materials to improve their mechanical properties and wear resistance, for example in the preparation of composites, coatings and reinforced plastics.

Biomedical: Graphene has potential applications in biomedical fields, including drug delivery, biosensing, tissue engineering, and cancer treatment.、

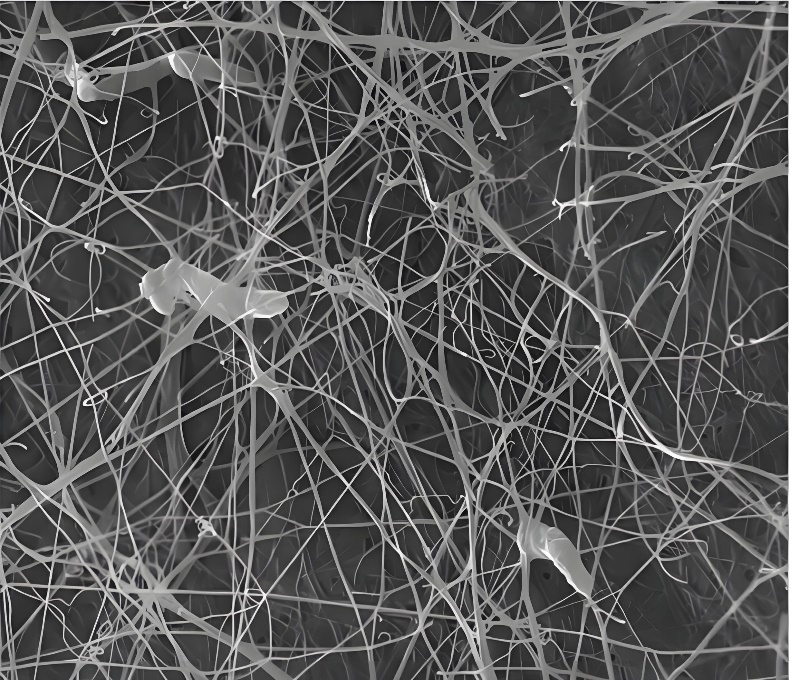

2. Nanocellulose:

Structure and nature:

Nanocellulose is a cellulose nanocrystalline or nanofiber composed of cellulose molecules, which has the characteristics of nanometer size and high crystallization. It can be derived from a variety of plant fibers, such as wood, cotton and pulp.

Nanocellulose is an ideal nanomaterial with excellent mechanical properties (strength and stiffness), high specific surface area, biocompatibility and renewability.

Application field:

Nanocomposites: Nanocellulose can be used as a reinforcing agent, compounded with polymers or other nanomaterials to improve the mechanical properties and impact resistance of the material, which is suitable for automotive parts, aircraft parts and building materials.

Nanocellulose films: Nanocellulose can be prepared into films with high transparency, flexibility and tear resistance for applications such as food packaging, optical films and biosensors.

Biomedical materials: Due to its biocompatibility and degradability, nanocellulose has a wide range of applications in the biomedical field, such as in tissue engineering, drug delivery systems and wound dressings.

Nanofiltration membranes: Nanocellulose nanofiltration membranes have a high porosity and surface area and can be used in areas such as water treatment, air filtration and biological separation.

3. methods post processing for material

1. methods post processing for 1 metal

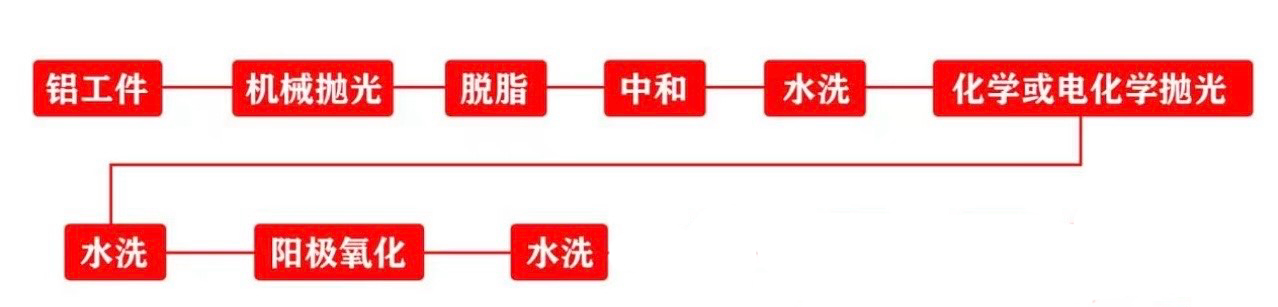

anodic oxidation

Anodizing is a common metal post-treatment method, mainly applied to aluminum and its alloys. The process is done by placing the aluminum product in an acidic solution containing electrolytes, making it act as an anode, and forming a dense oxide film on the surface of the aluminum through oxidation reaction under the action of an applied current. This layer of oxide film has good corrosion resistance, wear resistance and insulation, which can improve the surface hardness and weather resistance of aluminum products. Anodizing is commonly used in automotive parts, building materials, electronics and aerospace.

2.methods post processing for 1 plastic

Vacuum coating

The use of REDOX reaction, the metal ion reduction into metal, deposited on the surface of the material to form a protective, beautiful coating, often used in plastics, ceramics, glass and other materials. The workpiece requirements are low, the cost is high. Used in jewelry, digital accessories, mobile phone frame, badge, stamping hardware, crafts and so on.

3.methods post processing for wood

Wood painting

Wood painting is a common post-treatment that protects the surface of the wood and increases the beauty and durability of the wood. Here are the general steps for painting wood:

1. Surface preparation: Ensure that the surface of the wood is clean and smooth, free of dust, grease or other contaminants.

2. Primer coating: Select a primer suitable for wood, and use a brush or spray gun to evenly paint the wood surface. Primer can help enhance the adhesion and durability of the paint.

3. Sanding: After the primer has dried, gently sand the surface of the wood using sandpaper to remove any bristles or uneven areas.

4. Finish painting: Select the desired color of finish paint and use a brush or spray gun to evenly paint on the wood surface.

5. Drying and curing: Let the paint dry and cure in a well-ventilated environment.

The exact steps and methods of painting may vary depending on the type of wood, the type of paint, and the individual's needs. Before painting the wood, it is best to read the instructions and recommendations of the paint product and make appropriate adjustments according to the actual situation.

4. all materials in final project

1. Acrylic

Our team will choose acrylic as the main material of the algae tank, which is a common plastic material, also known as polymethyl methacrylate (PMMA). We chose it because:

Excellent transparency: acrylic material is very transparent, light transmittance of up to 92%, more transparent than glass. This makes it very popular in applications that manufacture transparent parts or require light transmission.

Weather resistance: acrylic has very good weather resistance to sunlight, ultraviolet rays and atmospheric conditions, is not easy to yellow or brittle, suitable for indoor and outdoor use.

Chemical resistance: acrylic has good chemical corrosion resistance, can resist the erosion of most common chemicals, and is not easy to be eroded by acid and alkali.

Machinability: Acrylic materials are easy to cut, carve, drill, hot bend and bond, and can be produced by various processing methods to create complex shapes and structures.

Light weight: Compared to glass, acrylic is less dense and lighter, making it more convenient in some applications.

Good insulation performance: acrylic is an excellent electrical insulation material, suitable for electronic devices and electrical equipment protective cover.

Recyclability: Acrylic materials can be recycled under the right conditions and are environmentally friendly.

2. Metal

The air pumps and other hardware we use are metal materials, such as all-copper filters, pure copper transformers and magnetic rings. The advantages of using metal as a housing are:

High mechanical strength: Metal materials usually have high mechanical strength and hardness, which can effectively protect the internal electronic components and mechanical components from external shocks and pressures.

Strong durability: The metal shell can resist wear and damage caused by long-term use and environmental changes, and has a long service life.

Good heat dissipation: Metal materials contribute to good heat conduction and can effectively dissipate the heat generated internally, improving the stability and performance of the equipment.

Corrosion resistance: Some metals (such as stainless steel, aluminum alloy, etc.) have good corrosion resistance and can remain stable under wet or harsh environmental conditions.

3.Silicone

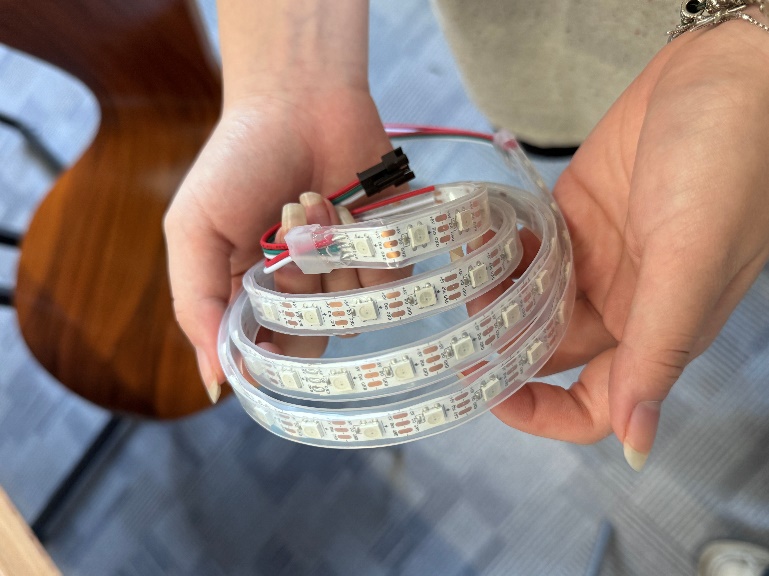

Our snorkel and lamp strip housings are made of silicone material,features:

Good flexibility and elasticity: silica gel has good elasticity, is not easy to deform, and has a certain softness, making it suitable for applications that need to bend or deform, such as seals and hoses.

Excellent electrical insulation: silica gel is an excellent electrical insulating material that can effectively prevent the current from passing through, so it is widely used in insulating parts of electronic, electrical and communication equipment.

Easy to process and manufacture: silica gel has good fluidity and formability, and can be made into products of various shapes and sizes through injection molding, extrusion and calendering processes.

Environmental protection: Silicone materials are usually recyclable and produce less waste during manufacturing and use, which is environmentally friendly.

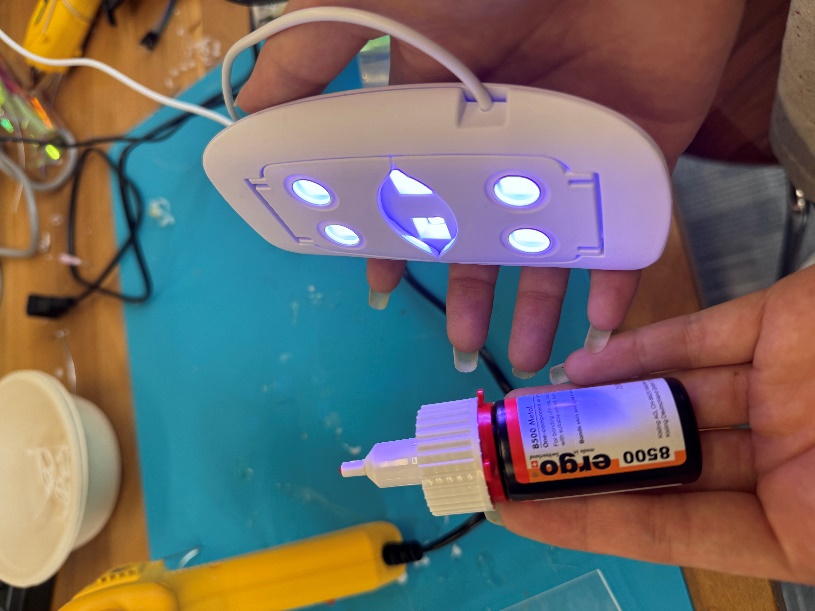

4.UV glue

When we make the algae tank shell, we use UV glue to connect the acrylic, for the following reasons:

Fast curing: UV adhesive can cure quickly under ultraviolet light, curing time is usually between a few seconds to a few minutes, with the characteristics of instant bonding.

Solvent-free: UV glue does not contain organic solvents, will not release harmful gases after curing, in line with environmental requirements.

High transparency: The transparency of UV adhesive curing is very high, similar to the transparency of glass, suitable for visually traceless bonding needs.

Excellent bonding strength: After UV adhesive curing, its bonding strength is very high, and it can firmly bond various materials, including glass, metal, plastic, ceramics and so on.

Temperature resistance and chemical resistance: cured UV adhesive usually has good temperature resistance and chemical resistance, and can resist high temperature and the erosion of some chemicals within a certain range.

Easy to control: UV glue can flexibly control the curing time and curing position during use, which is convenient for precise operation and production automation.

(上图为错误示范)